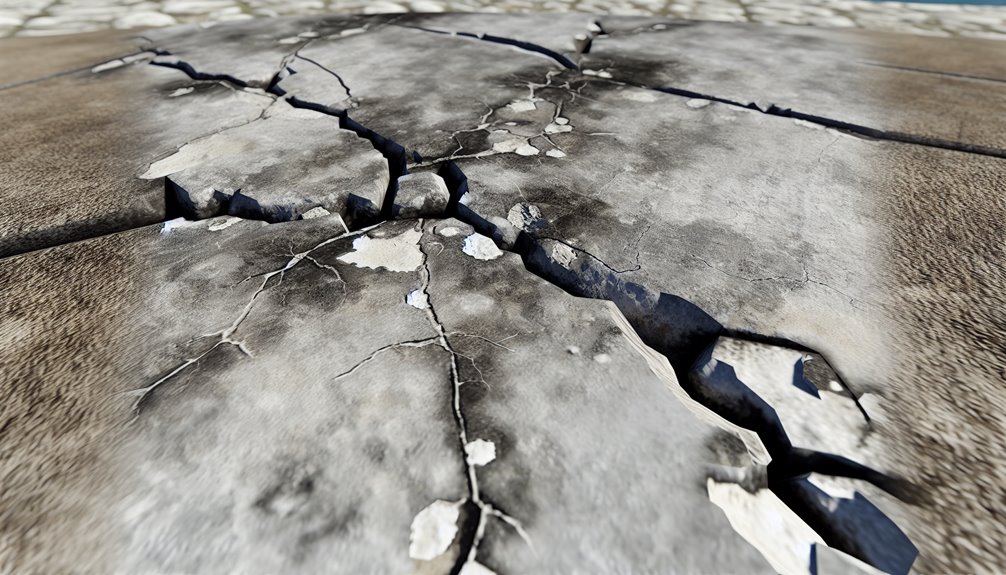

When you look at your concrete surfaces, do you notice cracks, spalling, or uneven colors? These common problems can compromise both the durability and the appearance of your structures. Cracks can emerge from various factors, while spalling often signals deeper issues with moisture. Additionally, color inconsistencies can detract from the overall aesthetic you aimed for. Understanding these challenges is vital, but what steps can you take to prevent them and restore your concrete's integrity?

Understanding Concrete Cracks

When it comes to concrete, cracks are a common issue that can arise for several reasons. You might notice them due to settling, temperature changes, or even improper curing. To effectively manage these cracks, you need to perform a thorough crack assessment. This assessment involves examining the type, size, and location of the cracks to determine their severity and potential causes.

As you observe the cracks, pay attention to crack progression; this refers to how cracks change over time. Some cracks may not seem significant at first but can expand and worsen if left untreated. By regularly monitoring these changes, you can take action before the damage becomes more extensive and costly to repair.

Understanding the underlying causes of concrete cracks can empower you to make informed decisions about maintenance and repair. Don't wait for small cracks to turn into major issues—address them early on.

Types of Concrete Cracks

Concrete cracks can be categorized into several types, each indicating different underlying issues. Understanding these types helps you assess the severity of your concrete problems.

Shrinkage cracks often occur as the concrete cures and dries, leading to plastic shrinkage during the early stages. These cracks may appear as hairline cracks on the surface.

Settlement cracks develop when the ground beneath the concrete shifts or settles, causing uneven support. You might notice these cracks forming in a pattern, often wider at the top than the bottom.

Expansion cracks result from temperature changes, causing the concrete to expand and contract. These can lead to surface cracks that disrupt the finish of your concrete.

Structural cracks, on the other hand, indicate more severe issues, often due to overloading or poor construction practices.

Random cracking can occur without a clear pattern, which might make it challenging to identify the cause.

Causes of Cracks

Cracks in concrete can stem from a variety of causes, each linked to environmental factors, material properties, or installation techniques. One common cause is shrinkage cracks, which occur as the concrete cures and dries. When the water content evaporates, the concrete shrinks, leading to tension that may exceed its tensile strength. You might notice these cracks forming in large, flat surfaces, like driveways or patios.

Another significant cause is settlement cracks. These happen when the ground underneath the concrete shifts or settles unevenly, often due to soil compaction or changes in moisture levels. As the foundation moves, it can pull the concrete apart, creating visible cracks. If you've noticed cracks near walls or around windows, it could be a sign of settlement issues.

Additionally, poor installation techniques can contribute to cracking. If the mix wasn't properly proportioned or the curing process was rushed, the concrete may not develop the strength it needs to resist cracking over time.

Understanding these causes helps you identify potential problems early, allowing you to take appropriate action before they worsen.

Repairing Concrete Cracks

Now that you understand the causes of concrete cracks, it's time to focus on how to repair them effectively.

You'll find that various techniques can restore your concrete's integrity, while also considering preventive measures to stop future issues.

Let's explore these solutions so you can keep your surfaces in top shape.

Causes of Concrete Cracks

Several factors can lead to unsightly cracks in your concrete surfaces, and understanding these causes is essential for effective repairs.

One common type is shrinkage cracks, which occur as concrete dries and loses moisture. You might also encounter settlement cracks when the ground beneath your concrete shifts, causing uneven settling.

Thermal cracks develop from temperature fluctuations that expand and contract the material. Loading cracks result from excessive weight or pressure on your concrete, while expansion cracks arise when the concrete's volume increases due to heat.

Hairline cracks, though often minor, can signal underlying issues and surface cracks might appear from normal wear and tear.

In some cases, structural cracks can indicate serious problems with the integrity of your concrete.

Repair Techniques Overview

When it comes to repairing concrete cracks, understanding the right techniques can make all the difference. You'll want to assess the size and type of crack first. For hairline cracks, a simple epoxy or polyurethane injection can effectively seal the gap and prevent further damage.

Larger cracks may require a more robust approach, such as filling them with specialized repair materials designed for structural integrity. Once you've selected your repair materials, surface treatments are essential for ensuring a lasting fix.

After applying the filler, consider using a concrete resurfacer to create a smooth finish that blends with the surrounding area. This not only enhances the aesthetic appeal but also adds a protective layer against moisture and wear.

For wider cracks, you might need to chisel out the edges before applying your repair material, ensuring a better bond. Always remember to clean the crack thoroughly to remove any debris or loose concrete before starting the repair process.

Preventive Measures Explained

Preventive measures are essential for maintaining the integrity of your concrete surfaces and avoiding costly repairs down the line. By focusing on crack prevention and spalling prevention, you can guarantee your concrete stays in top condition.

Start by choosing the right mix for your concrete. A well-balanced mixture with appropriate additives can improve strength and reduce the likelihood of shrinkage cracks.

When pouring, make sure to properly compact the concrete to eliminate air pockets that can lead to weak spots.

Another critical step is proper curing. Keep your concrete moist for at least a week after pouring to allow it to gain strength. If you live in an area with extreme temperatures, consider using insulation blankets to protect the surface during curing.

Regular maintenance is also key. Seal your concrete surfaces every few years to protect against moisture infiltration, which can cause spalling.

Additionally, routinely inspect for early signs of cracks or surface damage. Addressing these issues promptly can prevent them from worsening and leading to more extensive repairs.

What Is Spalling?

Spalling is a common issue that affects concrete surfaces, leading to flaking or chipping.

You might wonder what causes this problem and how you can prevent it from happening in the first place.

In this section, we'll explore the causes of spalling, effective prevention techniques, and repair solutions to keep your concrete looking its best.

Causes of Spalling

Many factors can lead to spalling, a common issue in concrete structures. One of the primary causes is moisture infiltration. When water seeps into the concrete, it can freeze and expand, leading to cracking and, ultimately, spalling. Poor drainage and inadequate moisture control can exacerbate this problem.

Additionally, using de-icing salts during winter can accelerate spalling by introducing harmful chemicals that penetrate the surface.

Another significant factor is the quality of the concrete mix. If the mix contains excessive air pockets or inadequate bonding agents, it can weaken the structure, making it more susceptible to spalling.

Environmental stressors, like rapid temperature changes, can also contribute to this issue. The constant expansion and contraction can create stress fractures, which may lead to spalling over time.

Lastly, neglecting regular maintenance can worsen the situation. Without proper inspections and repairs, minor issues can escalate into significant problems.

To mitigate spalling, prioritizing moisture control and adhering to quality standards during construction are essential. Remember, effective spalling prevention starts with recognizing these causes and addressing them promptly.

Prevention Techniques

Concrete integrity relies heavily on effective prevention techniques to combat spalling. To keep your concrete surfaces strong and durable, it's essential to implement proper surface treatments. These treatments can form a protective barrier, reducing the chances of moisture penetration that leads to spalling. You should consider sealants or coatings that are specifically designed to resist water and de-icing chemicals.

Moisture control is another key factor in preventing spalling. Make certain to address any drainage issues around your concrete surfaces, as standing water can exacerbate moisture problems. If you're pouring new concrete, choose a mix that minimizes water content while maintaining workability.

Additionally, maintaining proper curing practices during the initial setting period helps strengthen the concrete, making it more resilient against spalling.

Regular maintenance, including cleaning and resealing, will also extend the life of your concrete. By taking these proactive steps, you can greatly reduce the risk of spalling and guarantee your concrete remains in top condition for years to come.

Repair Solutions

Understanding what spalling is can help you identify the issues that arise even with the best prevention techniques in place. Spalling occurs when the surface of the concrete flakes, chips, or peels away, often due to moisture intrusion, freeze-thaw cycles, or improper curing.

When you notice spalling, it's essential to assess both the crack width and spalling depth to determine the appropriate repair solution.

For minor spalling, you can start by cleaning the area thoroughly, removing any loose debris. Then, use a concrete resurfacer or patching compound to fill in the damaged areas. Make sure you follow the manufacturer's instructions for the best results.

If the spalling is more extensive, you might need to contemplate a concrete overlay. This involves applying a new layer of concrete to restore the surface's integrity.

In severe cases, where the spalling depth indicates significant structural damage, you may need professional help. They can evaluate the underlying issues and provide more all-encompassing repairs, possibly involving replacement of the affected concrete sections.

Causes of Spalling

Spalling, a common issue in concrete structures, occurs when the surface flakes or chips away. You might notice this problem in driveways, patios, or sidewalks, where moisture, freeze-thaw cycles, and de-icing salts often take a toll.

One major cause of spalling is water infiltration. When water seeps into the concrete and freezes, it expands, leading to cracks and surface flaking as it thaws.

Another factor contributing to spalling is the use of low-quality materials during construction. If the concrete mix lacks proper adhesion or is susceptible to degradation, you'll likely face spalling issues later on.

Additionally, improper curing can weaken the concrete, making it more vulnerable to spalling.

Chemical reactions can also play a role. For instance, the presence of certain aggregates can lead to alkali-silica reactions, which might cause surface damage.

To address spalling, you'll need effective spalling repair techniques that restore the concrete's integrity. As you consider spalling prevention, remember to choose quality materials and guarantee proper installation and maintenance.

Understanding these causes can help you protect your concrete structures from further damage.

Preventing Spalling Issues

To keep your concrete surfaces looking great and free from spalling, proactive measures are key. Start by ensuring proper installation. Using high-quality materials and following industry standards during the pouring process can greatly reduce the risk of spalling later on.

Next, prioritize regular maintenance. Clean your concrete surfaces regularly to remove harmful chemicals, dirt, or debris that can contribute to deterioration. Sealants can be your best friends in spalling prevention. Applying a good quality sealant helps in creating a barrier against moisture, salts, and other elements that can penetrate and cause damage over time.

Another essential step is to control the environmental conditions around your concrete. Avoid using de-icing salts in winter, as they can lead to spalling. Instead, consider alternative methods for ice removal, like sand or gravel, which won't harm the surface.

Lastly, provide adequate drainage to prevent water pooling, which can contribute to spalling. By following these strategies, you can enhance surface protection and extend the life of your concrete, keeping it in excellent condition for years to come.

Color Inconsistencies in Concrete

Color inconsistencies in concrete can be frustrating, especially when you're aiming for a uniform look. You might notice variations in shade or intensity, often resulting from multiple factors. One common issue is color fading, which can occur due to sun exposure, weather conditions, or improper curing methods.

If you've mixed different batches of concrete, slight differences in materials can also lead to noticeable color discrepancies.

Another reason for inconsistencies can stem from surface treatments. If you apply sealers or stains unevenly, you might end up with patches that look different from the surrounding areas. It's important to follow application guidelines closely and guarantee that the surface is properly prepped to achieve a consistent finish.

Moreover, the type of aggregate and pigments you use can influence the final color. If you're using colored concrete, be aware that even slight variations in mixing or application can yield unexpected results.

Keeping these elements in mind can help you better understand and manage color inconsistencies in your project, securing that your concrete looks as close to your vision as possible.

Solutions for Color Problems

Addressing color problems in concrete requires a proactive approach that emphasizes consistency throughout the project.

First, you should assess the existing color inconsistencies and determine the best method for color correction. This might involve using a tint application to match the desired hue. Make sure you test the tint on a small area before full application to confirm it achieves the right shade.

When mixing concrete, maintain uniformity in your materials. Using the same batch of aggregates and pigments will help reduce variations.

If you're working on a larger project, consider using a ready-mix concrete supplier who can guarantee consistency.

For existing concrete that's already been poured, you can apply a concrete stain or dye to enhance the color. Be sure to follow the manufacturer's instructions for ideal results.

If spalling or fading has occurred, resurfacing the concrete with a colored overlay can provide a fresh look while solving the color problem.

Frequently Asked Questions

How Can I Prevent Future Concrete Problems?

To prevent future concrete problems, you should focus on regular preventive maintenance. Make sure you're applying proper sealing to protect against moisture and wear. This will extend the life of your concrete surfaces considerably.

Are There Specific Weather Conditions That Worsen Concrete Issues?

Yes, freeze-thaw cycles and high humidity levels can worsen concrete issues. When temperatures fluctuate, water trapped in the concrete expands and contracts, leading to damage. Monitoring these conditions can help you maintain your concrete's integrity.

What Tools Are Needed for Concrete Repairs?

To tackle concrete repairs, you'll need tools like a concrete mixer, trowel, and putty knife. For crack sealing, use a caulking gun, and for spalling repair, consider a chisel and concrete resurfacer for best results.

How Long Does Concrete Repair Typically Last?

Concrete repair typically lasts several years, depending on factors like installation quality and environmental conditions. To enhance repair longevity, follow maintenance tips like sealing and regular inspections, ensuring your repairs stand the test of time.

Can I Paint Over Concrete to Fix Color Issues?

Yes, you can paint over concrete to fix color issues. Just make sure to choose quality concrete paints and properly prepare the surface for the best adhesion and durability. It'll enhance your concrete's appearance greatly.

Conclusion

To sum up, addressing common concrete problems like cracks, spalling, and color inconsistencies is essential for maintaining the durability and appearance of your surfaces. By understanding the types and causes of these issues, you can take proactive steps to repair and prevent them. Using quality materials and proper maintenance techniques will not only enhance your concrete's longevity but also keep it looking great. Don't wait for problems to escalate—stay vigilant and act quickly to protect your investment!